This is the third part of a ten-part series on Hydraulics and Filtration, a general guide on hydraulic filtration systems. The third and fourth part are about the main types and common sources of contamination in these systems. This part will discuss solid particles, which are one of the most important contaminants of hydraulic systems. In the next part, we will continue this discussion to water and air as other common contaminants.

There are three major types of contaminants of hydraulic systems:

- Solid Particles

- Water

- Air

This chapter will review these contaminants and common damages associated with each, along with ways of preventing those damages.

Solid Particles

Types

Solid particles are classified into two groups: “silt” (smaller than 5μm in diameter) and “chips” (larger than 5μm in diameter). While silt can cause defects in components over time, the presence of chips can cause immediate disastrous damage in a system.

Solid particles can also be categorized into the following groups:

1. Hard Particles

- Silica

These are crystalline particles with a high hardness value that exist naturally as quartz and sand. When the concentrations of silica particles in the environment is higher, the particles are more likely to enter the system and cause damage. Damage caused by silica particles is usually direct. - Carbon

Carbon particles are commonly found as soot in work environments. These spherical particles tend to join together and form clusters. Carbon can cause damage to hydraulic systems directly or indirectly through chemical reactions with additives. - Metal

Metal particles are found in various forms in hydraulic systems. These particles can enter the system or be produced in the system through wear caused by solid particles. Metal usually damages the system directly.

2. Soft Particles

- Rubber

Rubber particles are commonly produced in damaged areas of sealing washers. These particles damage the system directly if they find their way in. - Fibers

Fibers commonly enter the system from the outside and cause direct damage. - Microorganisms

Microorganisms are microscopic living organisms that enter the system through the fluid or other means. These organisms can grow inside the system and react with additives, which could create corrosive or otherwise damaging compounds.

As mentioned before, contaminants usually enter the system from the outside. It is important to note that solid contaminants can also cause indirect damage to the system. For example, formation of silt in fluids as a result of chemical reactions in deposited matter can highly alter fluid properties and deteriorate its quality.

Damages

Presence of solid particles in any part of hydraulic systems can cause different types of damage to these systems. Each of these types are discussed below:

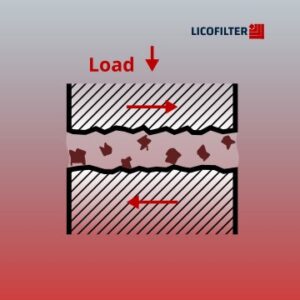

Abrasion

When solid particles enter the space between two moving surfaces, they can cause abrasive wear on one or both of them. The amount of abrasive wear is dependent on the relative hardness of the particles and surfaces. The harder a particle is relative to a surface, the more abrasive wear it will cause on the surface.

Erosion

When the fluid moves in high velocity, floating solid particles collide with the component’s corners and inner walls and erode these surfaces over time.

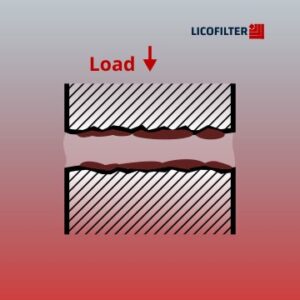

Adhesion

Lack of proper lubrication between moving components can cause clumps of solid particles stick to components’ inner surfaces. This will cause the surfaces to lose their evenness. It is noteworthy, that this is the only type of damage by solid particles which causes swelling. Other types of damage usually create cavities on surfaces.

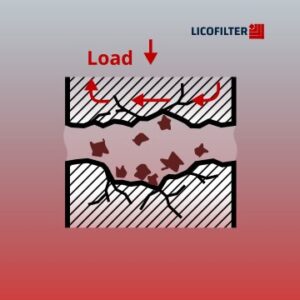

Fatigue

Constant impact of solid particles on inner surfaces causes surface stress to rise. With more impacts over time and more serious surface stress, small parts of surfaces are chipped away. These chips then enter the system and cause more damage over time.

Corrosion

Some forms of solid contaminants such as microorganisms and soot particles chemically react with additives and form new compounds like acids, which will corrode surfaces.

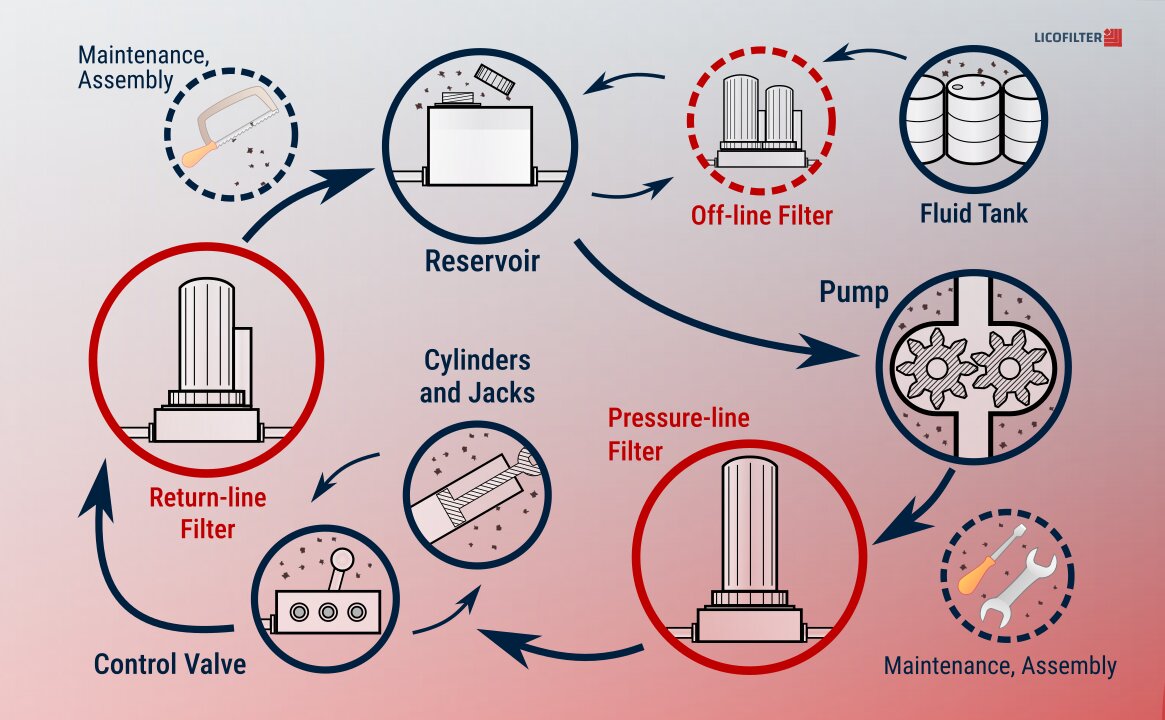

Damage Prevention

Solid particles can enter a system through different ways. For example, during the manufacturing, assembly, maintenance or operation of a system, new solid particles are created through abrasion, corrosion or similar processes. Moreover, solid particles can enter a system through leaking holes, enter with new fluid or in other similar ways.

The most important measure in restricting damage caused by solid particles is preventing their entry to the system in the first place. Separation methods such as filtration are more efficient when there are fewer particles in the hydraulic fluid.

Table below shows some typical ingression rates of particles into hydraulic systems in different environments.

Ingression rates for common hydraulic equipment in different environments

| Environment | Ingression Rate (per minute)* |

| Mobile Equipment | 108~1010 |

| Production Halls | 106~108 |

| Assembly Facilities | 105~106 |

* Number of particles larger than 10μm entering the system from various sources

There are different measures for preventing solid particles from entering a system, including:

- Proper storage

- Use of breather filters on reservoirs

- Draining the fluid before the initial operation of the system

- Checking all seals periodically and replacing worn parts

- Covering all openings during maintenance

- Filtering the fluid before filling tanks

Preventing contaminants from entering hydraulic systems requires great care and attention. This must be taken into account in all units that employ hydraulic components.